Felt and wire autoguide systems are designed to keep the felt / wire running properly in the centre of the roll over which it travels. If you lose control over your wire, felt or fabric, the cost incurred in damaged clothing is high and production loss makes such accidents even worse.

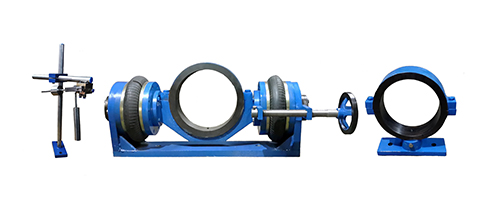

Installing the reliable and well proven automatic wire & felt guiding system is an easy and inexpensive way to avoid such problems. It comprises of an actuator and a pneumatic controller. The auto guide works without any sliding surfaces.

Features:

- It has very few moving parts which leads to very nominal need for maintenance work.

- The moving parts are fully enclosed for complete protection against water, fibre and dust.

- It gives immediate response to any movement of the clothing in the cross machine direction without over compensation.

- Very low consumption of compressed air normal working pressure is 3.0 kg/cm2

- It can be installed in any position i.e. horizontal, Vertical, inclined or even upside down.

- Easy to install and operated

- No adjustment required before start up

- Built in manual override.

Advantage:

- Avoid fabric run off.

- Optimize paper productivity

- Minimize Fabric edge wear

- Reduce Sheet breaks

- Reach maximum fabric life.